Starting a commercial bakery requires careful planning and the right set of machines to ensure smooth operations, consistent quality, and high productivity. Choosing the right equipment can streamline production, reduce manual effort, and help deliver the perfect baked goods every time. Here are five essential machines that every commercial bakery should consider.

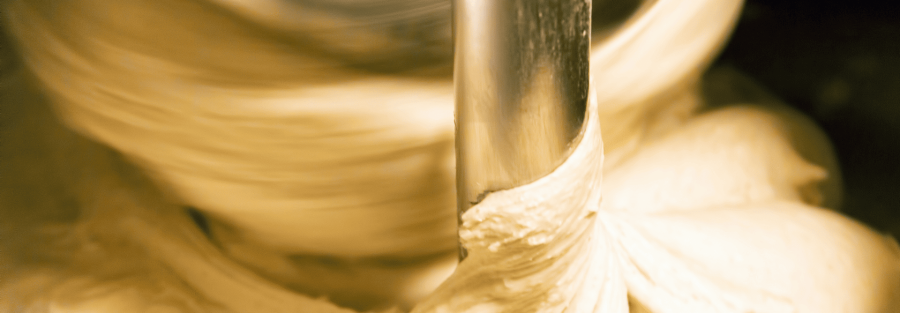

Dough Mixer

Mixing is where your dough’s structure, texture and consistency are defined. A proper dough mixer handles large batches, ensures uniform distribution of ingredients and sets you up for consistent product.

- Capacity aligned with your production volume (e.g., 50 kg, 100 kg bowls)

- Robust motor and durable build — start‑ups don’t have time for constant breakdowns

- Versatility: able to handle different dough types (lean bread, enriched doughs)

- Safety features and ease of cleaning (hygiene is non‑negotiable)

Dough Divider & Rounder

Once the dough is mixed, you need consistent portion sizes. A dough divider saves time, reduces human error, and ensures uniform pieces that bake evenly which is vital for commercial production.

- Accurate weighing/portioning mechanism

- Capacity matched to throughput (how many pieces per hour)

- Adjustable for different product sizes

- Ease of cleaning and sanitation

Proofer Room

Proofing influences the rise, texture, flavour and final appearance of your baked goods. A dedicated proofer ensures you maintain consistent temperature & humidity critical in the UAE’s climate.

- Controlled temperature and humidity settings

- Clear visibility (for monitoring)

- Good airflow and even proofing throughout

- Size aligned with batch volume

Commercial Oven (Deck, Rack or Conveyor)

The oven is the heart of the bakery. The right oven type determines capacity, product type, energy usage, footprint and ultimately your output and quality.

- Precise temperature control and uniform heat distribution

- Fit for your product mix (e.g., artisan bread, Arabic bread, buns, pastries)

- Efficient energy usage (important in UAE)

- Adequate capacity for your initial and growth needs

Sheeter / Dough Flattener

If your bakery includes flatbreads (like Arabic bread, Lebanese bread) or layered pastry products, a sheeter/flattener is critical. It ensures uniform thickness, faster processing, and consistent quality.

- Adjustable thickness settings

- Robust build to handle repeated use

- Safety features (guards, emergency stop)

- Suitable for your dough types (flatbreads, pastries)

Starting a commercial bakery in the UAE or Gulf region is a bold and exciting endeavour. With the right backbone of equipment from mixer to sheeter, divider to proofer, and oven to finishing you set yourself up not only for day‑one launch, but for sustainable growth. At East Gate Bakery Equipment Factory, we are ready to partner with you: supply the machines, provide installation, training and after‑sales support, so your bakery becomes a success story.

Bonus Tips for Start‑ups Using East Gate Equipment

- Plan for Growth: Choose machines that cover both current volume and foreseeable ramp‑up, so you don’t instantly outgrow them.

- Space & Utilities: Ensure your site has proper ventilation, power supply, water drainage and floor space arranged for workflow from mixing → proofer → oven → cooling/packaging.

- Training & Maintenance: East Gate offers training and maintenance services globally.

- Product Mix Flexibility: If you plan to serve different types of bread (artisan, flatbreads, buns) make sure your machines are versatile or modular — East Gate’s equipment supports “international bread section” as well as regional bread types.

- Energy Efficiency & Sustainability: With UAE climate and energy costs, choosing machines optimized for efficiency makes a real difference. East Gate cites their commitment to economy and superior standards.

Let us bake the future together. Visit our website www.eastgatefactory.ae to explore the machine line‑up, get a quote and kick off your bakery journey.